Compression Limiters are used to protect plastic components in bolted joints and maintain a threaded fastener’s clamp load by eliminating plastic creep. To function properly, bearing surface beneath … [Read more...] about How to Ensure Bolted Joint Integrity When Using a Compression Limiter in a Plastic Assembly

Fastening & Joining

How to Maximize Retention of Spring Pins

When proper design guidelines are followed, companies can take advantage of the many benefits that Spring Pins offer. They significantly reduce the total cost of the assembly, lower insertion forces … [Read more...] about How to Maximize Retention of Spring Pins

How to save money and improve productivity with the next generation of vibration-resistant fasteners

The problem: Not all vibrations are good vibrations A properly designed joint utilizing a nut and bold worked perfectly for over a century in applications without vibration. Unfortunately, many … [Read more...] about How to save money and improve productivity with the next generation of vibration-resistant fasteners

How To Choose Fasteners That Maximize Assembly Life

Fasteners are usually the smallest, least expensive components within an assembly. Even though fasteners usually hold the entire assembly together, they are often overlooked until … [Read more...] about How To Choose Fasteners That Maximize Assembly Life

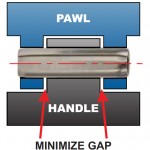

How to Design the Optimum Hinge

There are two primary types of hinges: A free fit hinge has little to no friction or drag when the latch or handle is rotated. Hinge components are “free” to rotate independent of one another. A … [Read more...] about How to Design the Optimum Hinge

How to Control Shim Tooling Costs

SPIROL has several manufacturing methods that eliminate or greatly reduce tooling expenditures. Shim tooling costs are one of the quickest ways to drive a prototype or short-run production project … [Read more...] about How to Control Shim Tooling Costs

How To Choose the Most Cost Effective Alignment Dowel

There are many ways to align components — the challenge for Design Engineers is choosing the best solution at the lowest cost. The most common, and often most expensive, Alignment Dowels are … [Read more...] about How To Choose the Most Cost Effective Alignment Dowel

Case Study : Robotic Dispensing of Appliance Adhesives Improves Quality, Reduces Cost

Background: The appliance industry bonds glass directly to oven door panels. Their adhesive choices are either very high bond double-sided adhesive tape or a liquid adhesive such as 2-component … [Read more...] about Case Study : Robotic Dispensing of Appliance Adhesives Improves Quality, Reduces Cost

Conventional Fasteners Can Bring Multi-Million Dollar Machines to Their Knees

For fail-safe joint integrity in critical applications, US industry is adopting an innovative fastener locking system that can stop joint failure and production downtime by preventing thread … [Read more...] about Conventional Fasteners Can Bring Multi-Million Dollar Machines to Their Knees

Installation of Self-clinching Fasteners in Thick Sheets

Self-clinching fasteners are pressed into holes in ductile metal sheets to create a permanent union with the host material and replace one or more pieces of traditional loose hardware or … [Read more...] about Installation of Self-clinching Fasteners in Thick Sheets